Barrier Strip RTSQF - Did you know that...

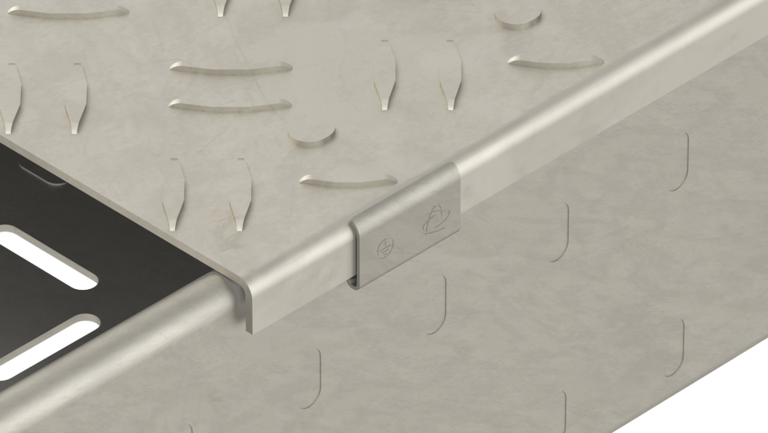

... our RTSQF barrier strip can not only separate when changing direction, but also support the lids of walk-on systems in the same operation?

Standard barrier strips can only be laid in changes of direction such as horizontal elbows or crosses with great effort. This interrupts the fanned cable routing in fittings, for example, which can have a negative impact not only on the shielding of cables, but also on the support of covers for walkable cable tray systems.

The flexible RTSQF barrier strip was designed to overcome this problem.

The barrier strip can be bent to suit the requirements and even cut to length by hand. This ensures continuous separation, especially for shielding interference-sensitive cables.

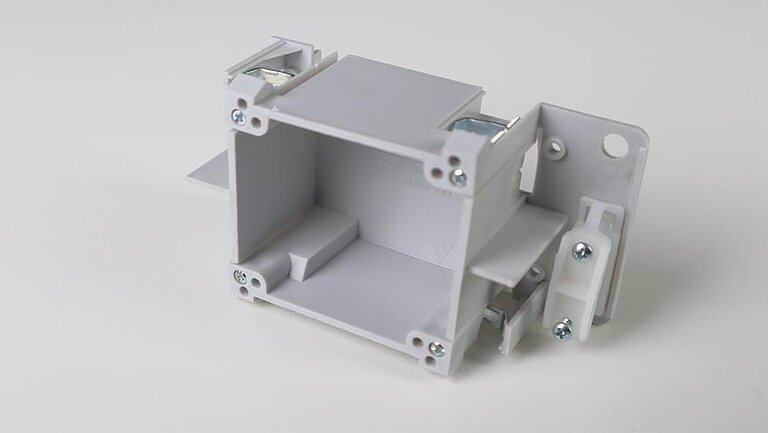

Before laying, the required length of the barrier strip in the bend is first determined. The RTSQF is then cut to length at the appropriate point by separating the corresponding segment. Dividing the RTSQF into segments of 50 mm each makes it easier to cut to the approximate length required.

No tools are required to separate the segments of the RTSQF. The segments can simply be separated by hand at the desired point by bending them alternately. The break point remains burr-free and does not need to be reworked to protect the cables.

The RTSQF can also be bent to the desired bending radius quickly and easily by hand. The barrier strip can be bent in both directions.

Depending on the distribution of compartment sizes in the trunking, the covers may be insufficiently supported in some cases.

These areas of the cable route are often found to have inadequate step support during final route inspection.

The RTSQF can also be used in this case. Small segments left over from the installation can be used as additional support at critical points.